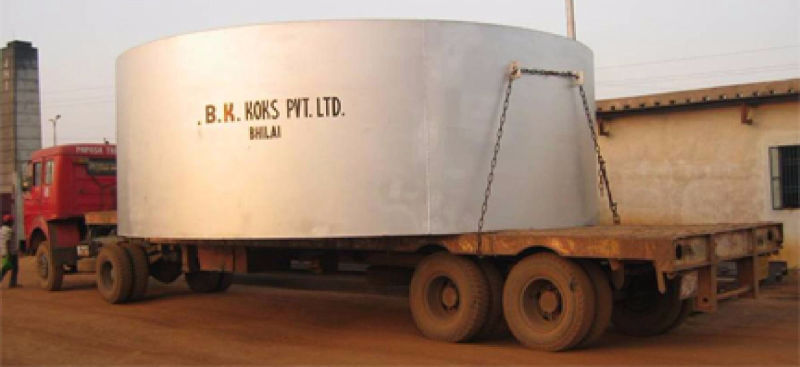

MIPL is proud to be associated with the following Industries that are a part of the ambitious Make in India Campaign unveiled by theHonorable Prime Minister Shri. Narendra Modi.

Industries Served :

THERMAL POWER, CONSTRUCTION, MINING, TRANSPORTATION,

OIL AND GAS, RAILWAYS,

CHEMICALS & PETROCHEMICALS

Social Media Links